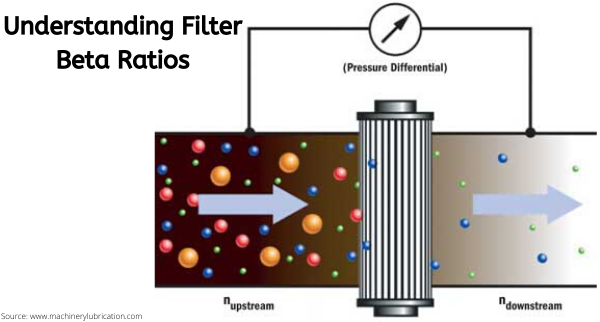

Understanding of the BETA Factor.

We concluded in our last article on Beta Factor . In this article, we will talk more about BETA Factor for buying new filters. What is the Beta Ratio? The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999 How is it measured? The test involves adding particles of a known size to the test fluid until the fluid reaches a saturation point and then bringing the filter online to remove particles in one pass through the element. It is important to consider that the beta ratio is valid for a particular size of the particle. For Example for a 5-micron filter, how many particles are above 5-micron mark in upstream of the filter and how many are downstream is measured. And then by using the below formula, the Beta Ratio is calculated. Source: https://www.machinerylubrication.com/ Each Beta factor corresponds to an efficiency of the filter