All about Oil Filters

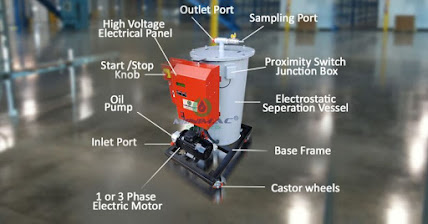

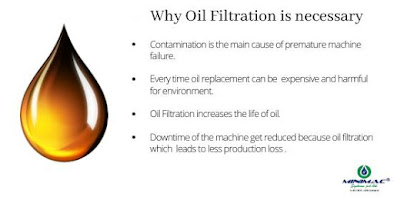

Lubrication Reliability is becoming an important aspect in industries such as Oil and gas, power generation, cement, metal and mining, steel, and many more. There are various activities performed under that such as oil condition monitoring and analysis, oil filtration, oil flushing, filter replacement etc. If the above mentioned activities are not followed timely or the lack of incorrect knowledge on maintenance practices may lead to some serious problems technically as well as financially. In this article, we are discussing the advantages of oil filtration and tips to buy the right oil filter. Can periodic oil replacement be a good option to avoid premature machine failure? As per the international standards like NAS/ISO, new oil is not completely clean. Some of the main reasons behind that could be poor storage practices or lubrication packaging. The proper monitoring and filtration of oil are more of a good option to avoid premature machine failure. Here are some of the benef