Case Study 3

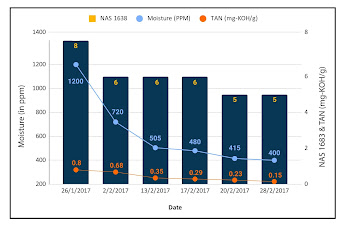

Case Study : A power plant in western India using Chinese technology turbine EHC system saved 3.01 Cr approx. With MLC LVDH TRIX-20 EH Oil filtration. Synopsis : A power plant (2 * 600 MW) in western region of India was struggling with the rapid increase in TAN values in the EH oil of the governing system of the turbine and moisture content was also more than permissible limits. Degradation of the oil was due to contamination ingression into the system and resulting in the formation of by-products. Minimac’s EH Oil Reconditioning system “MLC LVDH TRIX 20” act as a savior for the plant which has escaped the unexpected shutdown of the turbine worth 2.8 Cr (approx 48 hours downtime) and cost and effort for replacement of Oil worth 21 lakhs. In total, the company has saved around 3.01 Crore by installing an external Reconditioning system at their site. Problems : Failure of servo valve, Hunting and sluggish behavior of the turbine, Unplanned shutdown, Presence of varnish & silt in th